THE INDUSTRY & THE PRODUCT LINE

The water purification industry is highly diversified in terms of need, suppliers and users.

This process referred to as "The System," should be feasible for a wide range of unit sizes and for a wide range of liquid purification purposes. New technology, design and materials should permit Cellini CAST Technology Inc. to produce systems as small as 30 gallons per day (GPD) up to 75,000,000 gallons per year (GPD) capacity.

Systems in the 30-2000 GPD range can be used to desalinate sea water, to provide boiler feed and potable water for small and large pleasure boats and bigger systems for large merchant and navel ships. Systems in the 1,000,000 GPD to 75,000,000 GPD can be used to purify water for private industry, towns and cities and treat irrigation waste water as is done in the western United States.

To emphasize our commitment to this end, the following are two research and development projects, cooperatively being developed by the Cellini CAST Technology Inc. research team.

THE SYSTEM

Why is it called the System:

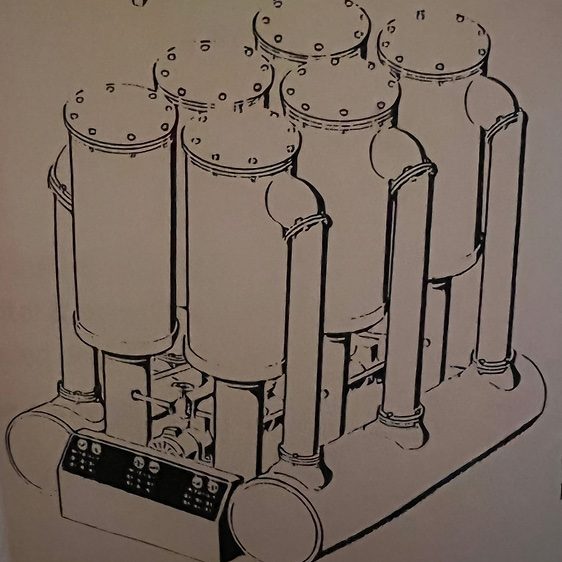

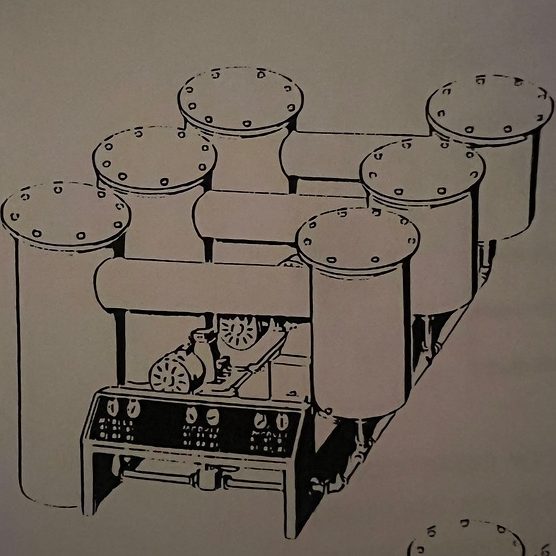

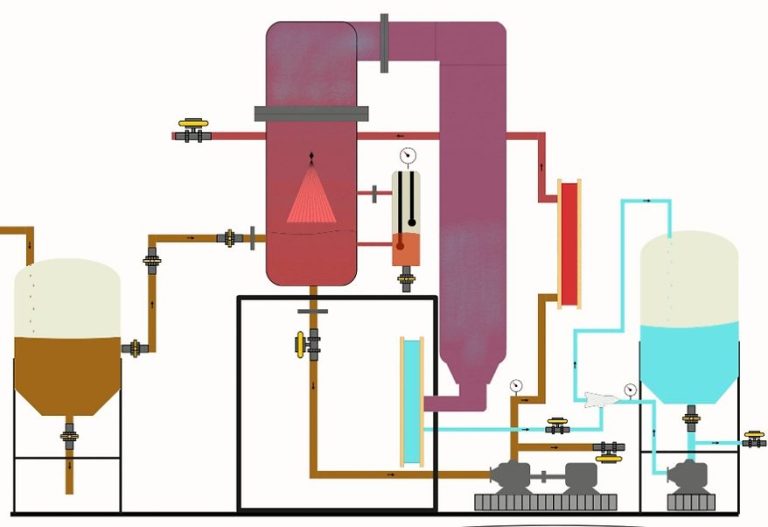

The Cellini Cast System is a compilation of cylinders, pumps, digital & remote controls, gauges, sensors, pipings, wirings etc., all placed on a stationary, mobile or floating platform.

The name (THE SYSTEM) is most appropriate.

EXECUTIVE SUMMARY

in August of 1984, Mr. Giovanni Vincenzo Cellini organized a corporation to develop and manufacture a liquid purification system. On September 13, 1988 a patent was granted and assigned to this corporation.

Through the following years the company was successful in receiving favorable technical assessments, verifications and acceptances from various State Agencies, specifically, Departments of Environmental Protection, including the US EPA.

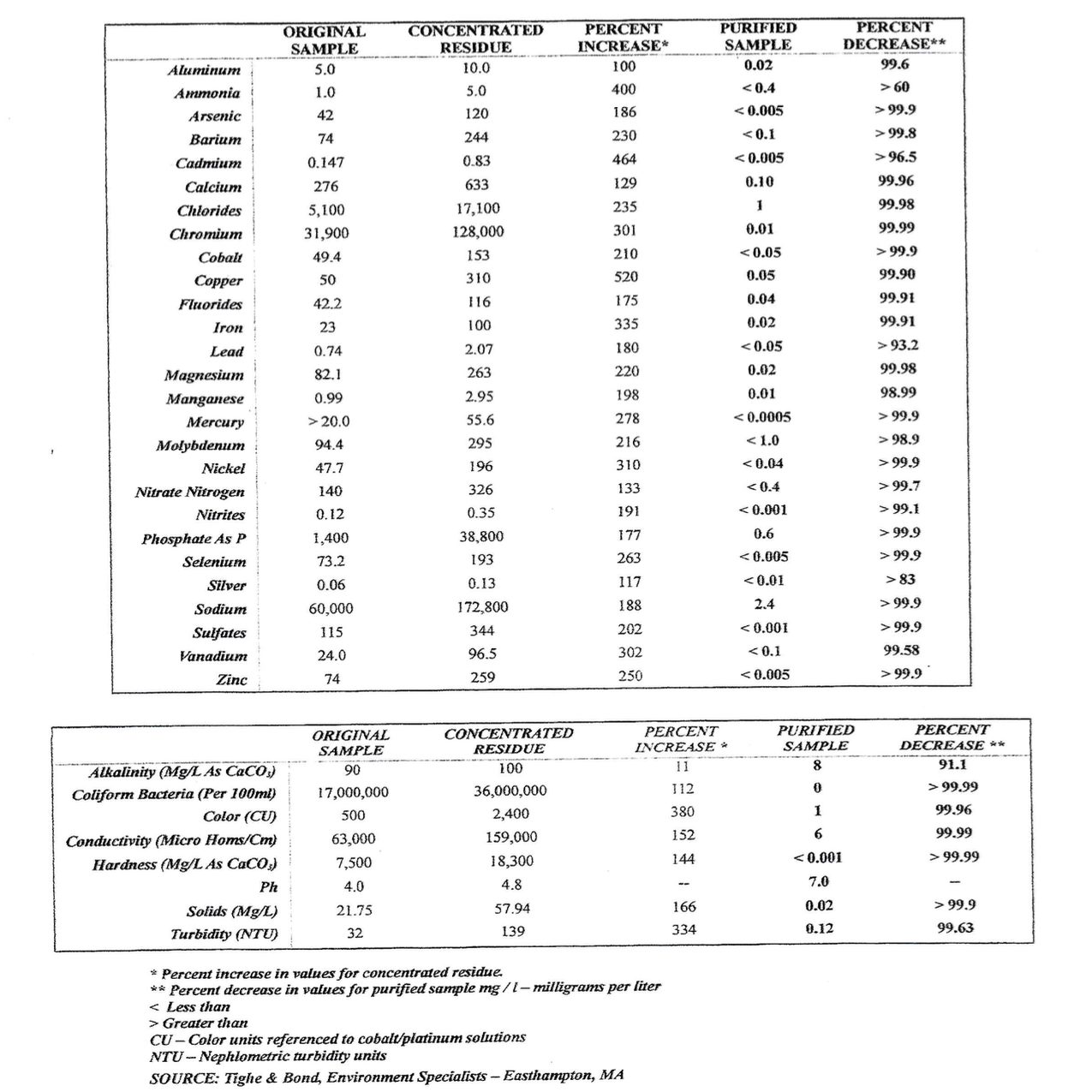

The System was specifically tested for the major environmental problems afflicting life itself, among the worst, the plating industry, and it superbly succeeded in all aspects.

The company was successful in marketing and selling the system to varied industries.

In 1996, Mr. Cellini retired and in 1997 completely separated from the company.

Prior to this, Mr. Cellini proudly served in the US NAVY, and honorably discharged, attended various trade schools, owned and operated Global Travel Agency and Cellini Tours Inc

While retired in Florida, Mr. Cellini continued to research ways to improve the system so that it would meet any new challenges and meet any new requirements and demands imposed by new technologies and the PA, so in 2015 Mr. Cellini organized a new corporation, CELLINI LPS, Inc. and in August of 2022 the corporation was renamed to:

Cellini CAST Technology Inc.

CAST stands for our Intellectual Propriety Technology

(Controlled Atmosphere Separation Technology)

Cellini CAST Technology, nicknamed "Cellini or CAST System for short, utilizes flash distillation and vacuum evaporation technologies in conjunction with a liquid/vapor separation system and a proprietary energy recovery process.

Evaporative technology alone has not been successfully used in pollution prevention applications (merely transfers pollutants from one medium to another), but when combined with distillation technology, successful conversion applications have been demonstrated.

The CAST System is a refinement of existing applications of evaporation/distillation technology, eliminating common problems of entrainment, scaling, foaming and carryover.

The general process flows for the CAST System consists of one influent stream (the contaminated wastewater or process water), from which two streams are generated: A condensate (clean water), and a concentrate (which may be recovered for reuse/recycle onsite or off site.

CONTROLLED ATMOSPHERE SEPARATION TECHNOLOGY - CAST®

Our versatile, award-winning CAST system can be utilized as an effective stand-alone

wastewater or chemical recovery system, or as part of an integrated plant-wide conversion solution.

The CAST wastewater and chemistry recovery system eliminates costly disposal of hazardous waste or process effluent. The Zero-Liquid-Discharge (ZLD) program can recover nearly 100% of your valuable chemical resources or wastewater for immediate reuse or recycling at your facility.

CAST concentrates mixed hazardous waste down to as little as 5% of its original volume for economical disposal or reclaim.

This patented technology and all Cellini CAST Technology Inc. product lines are designed and constructed to exceed the demands of harsh chemical environments.

Best of all, the CAST process and the separation principles it's based on virtually eliminate the need for pretreatment.

Typical applications include:

► Zero-Liquid-Discharge wastewater recycle/reuse and elimination of a discharge

► BOD removal and subsequent recovery of sugars, proteins, starches and yeast as a

salable product

► Recycling of valuable chemical resources (electroplating solutions, acids, alkaline

cleaners and coolants

► Recovery of industrial chemicals including VOCs, ketones, dissolved gasses, alcohols, glycols, solvents etc.

► Concentrating process solutions for cost-effective reclamation of precious metals,

e.g., gold, silver, platinum

► Direct replacement of atmospheric evaporators and vacuum evaporators

pretreatment.

From a toxics use reduction standpoint, the system is optimally operated at the pollutant generation (source) point, but has also been used for end-of-pipe waste reduction.

Examples of applications for which the CAST System has been demonstrated include:

Chromic acid recovery from a chromate conversion coating operation

Recovery of silver and gold cyanide plating solution

Selected chemical solutions from process operations used in metal finishing

Electronics (including printed circuit board manufacturing and semiconductor module assembly processing)

Photochemical machining

Other similar industrial operations

CAST Systems can be manufactured to any specs and sizes (gallons per hour processed), will be built using stainless steel and compatible materials. The systems are also available as mobile (wheeled flatbeds) or floating (self-propelled barges/catamarans) self-sustainable units).

The operating cost range from $0.002 to $0.005 per gallon.

SUMMARY OF CAST SYSTEM CAPABILITIES

Controlled Atmosphere Separation Technology by Cellini, has been successful in providing reusable rinse water and recovering from the plating solutions of various metal finishing operations the following elements:

Nickel Chloride

Nickel Sulfate

Nickel Sulfa mate

Zinc Chloride

Cadmium Cyanide

Silver Cyanide

Gold Cyanide

Zinc Cyanide

Brass Cyanide

Chromic Acid

Additionally, CAST systems have successfully purified water containing:

Sewage

Particulate matter

Dissolved organic and ionic contaminates

CAST systems have separated water from oils, recovered etchants, and cleaners, solvents (chlorinated hydrocarbons) and process chemicals for reuse, and concentrated plating solutions, spent detergents and end of pipe waste streams for disposal or reuse.

CAST systems are also capable of generating ultra-pure water from city waste water sources and potable water from seawater, for the mining industry, within co-generating power plants, and to dealcoholize wine and beer. * (Refer to Note) CAST systems may be utilized virtually anywhere.

Thermal, solar, or wind power can easily be used.

Thermoclines * (Refer to Note) A Steep temperature in a body of water such as a Lake, Sea, Ocean, Marked by a layer above and below which the water is at different Temperature/Pressure: Hydrostatic Pressure

THE CAST SYSTEM COMPARISON

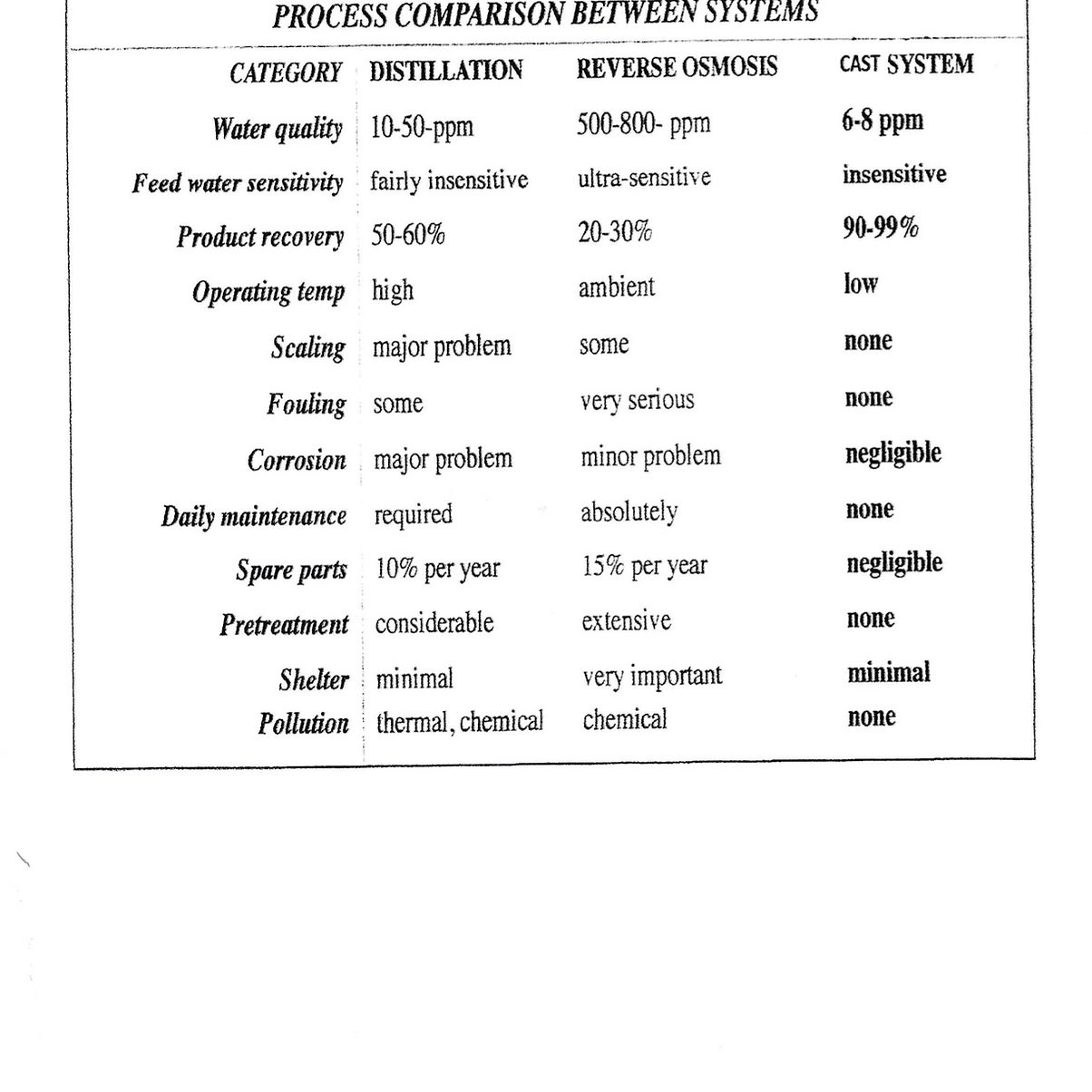

The two principal systems of liquid purification in use today are reverse osmosis and deionization. These types of systems require pre- and post-processing treatment, utilize filters, membranes and/or chemicals, require regular monitoring of the feed source and maintenance, and demand a sizable footprint. Thus, in addition to the basic purchase cost of these types of systems, additional costs must be factored in, such as the costs to maintain a constant presence of trained personnel, provide safe storage of expensive replacement membranes, filters and/or chemicals and ensure the safe disposal of the used elements.

The CAST system employs a natural process, using neither filters, chemicals, or moving parts other than pumps, to purify the liquid being processed. It requires no pre- or post-processing treatment, needs no constant monitoring, can be operated by semiskilled personnel, and runs on a continuous basis. A computer, smart phone or tablet can remotely monitor the CAST system.

These combined factors render this system efficient, effective, and economical. The liquid is processed through a separation chamber where the atmospheric pressure is at a high vacuum, separating the liquid from the contaminants and greatly reduced in volume and since they are not altered in its pure form, can be recycled or reused.

THE INDUSTRY & THE PRODUCT LINE 2

The liquid purification industry is highly diversified in terms of need, suppliers, and users. The CAST System can be adapted to a wide range of unit sizes and of liquid purification and waste concentration purposes.

New technology, design, and materials will permit Cellini to produce systems as small as 30 gallons per day (GPD) capacity up to any (GPD) capacity needed.

Systems in the 1,000,000 GPD to 75,000,000 GPD range or larger, can be used to purify water for private industry, towns, and cities and treat irrigation waste water as is currently done in the western United States.

THE MARKETPLACE

The CAST System is designed to treat liquids and wastes of virtually any volume and any chemical makeup, relying on the combined powers of flash distillation and vapor recovery. Since it is particularly effective for the treatment of inorganic chemical wastes, one of many target markets would be the metal finishing and electronic industries.

Applications in these industries typically involve volumes of five gallons per minute or less;

Discharge limits for chemicals are stringent; and chemicals used in the process are expensive but recoverable by The CAST System for reuse.

THE FOLLOWING ARE THE MAIN INDUSTRIES THAT CAN USE THE CAST Systems:

Desalination

Contaminated Water

Petroleum

Fracking

Plating

Electronic

Microchip

Paper

Aerospace

Beverage

Textile

Food Processing

Pharmaceutical

Tourism

Infrastructure

Carbon Conversion

THE PRODUCT

The CAST System is capable of processing any contaminated liquid, be it seawater, sewage, or chemical waste. It can provide nuclear and boiler grade water, treat effluents from acrylic electro-painting and all types of electroplating, recover solids, solvents, and so forth for reuse, precluding potential waste disposal problems.

The CAST System provides a range of mobile options which allows on-site treatment feasible. Simplicity and practicality are the key elements to the The CAST System.

The CAST System is comprised of a cylinder, a vacuum, and circulating and discharge pumps, all controlled by a digital control panel.

Due to the simplicity of design and assembly and its practicality of use, CAST Systems do not need experts or engineers to operate them. The company can now envision manufacturing the systems to meet all present and future water purification needs.

MARKETING

This process, referred to, as "Cellini CAST System" is feasible for a wide range of unit sizes and for a wide range of liquid purification purposes.

The CAST System will either be sold or leased. The leasing option is the most lucrative and lasting.

DISTRIBUTION

Cellini will utilize a sales force knowledgeable in all aspects of pollution and purification fields and maintain updates on any existing and new EPA mandates.

CUSTOMER SERVICE

Under the standard purchase or lease agreement, the company will provide, at the time of installation, basic instruction in the proper use of the system, and in the effective utilization of its capabilities to fulfill that particular customer's needs.

Servicing of the system after installation will be offered at additional charge on either a contract or an "on demand" plan.

MANUFACTURING

The manufacturing activities of CELLINI will consist of the assembly of components parts into finished systems. The Cellini technicians will join the chambers into completed units, secure the cylinders, pumps and control panel to the frame, install the proprietary assembly, make the final connections and test the unit before delivery.

he proprietary assembly will always be manufactured in-house.

COMPETITION

CELLINI believes that its products will compete favorably in areas of system features, design, performance, reliability, and price.

A new system is being readied to be used in the total conversion and neutralization of CO, GAS with the final result of a reusable product.

The complete process is explained and demonstrated through our visual presentation.

BENEFITS derived from the new generation of CAST SYSTEMS include:

Lowest energy cost per gallon ($0.002 - $0.005)

No metallic parts within system; totally chemical resistant

stainless steel parts

Guaranteed not to scale or corrode

Returns up to 99% of feed as de-ionized water

Concentrate returned is as little as 1% of feed

Possible re-use of concentrate

Possible sale of concentrate

Reduces disposal cost to a minimum

Reduces EPA & DEQE inspections

Eliminates EPA & DEQE fines

Continuous operation

Completely automatic operation

No operator required

Fail-safe controls

Quiet; minimal operating noise

Uses warm water flow to rinse tanks

Adaptable to any effluent

Short pay-back period

Minimal servicing required

Adaptable sizes (amount of output)

No high-load electrical power board needed

Short delivery time

Reduction of water-use cost

The price of the CAST SYSTEM will include:

System's cylinders with inner accessories+

Circulating & discharge pumps

Control console

Frame and cover

If the buyer does not have a continuous operating, adaptable heat source, the unit will then come with a hot water heater.

If the buyer does not use a cold water flow compatible with the CAST SYSTEM, the unit will also require an evaporating tower.

Placement Plan

The strategy is to sell the Systems, but more importantly is to lease them. Past experience dictates that such Systems, based on size requirements, and additional maintenance costs, may demand a very large output of cash.

Most companies, are reluctant to spend large sums and pay for additional maintenance costs for Systems that they may not understand or believe that they need.

Prior to approaching a prospect

Prior to approaching a prospect, CELLINI will research the needs, costs of operation/disposal of the elements to be treated. Based on this research CELLINI will propose to prospect, a lease agreement, including a maintenance program, in an amount totaling less than their present cost of said operation/disposal of the elements treated. In addition, with a CAST SYSTEM in operation, there will be no need for any EPA or other permits, this additional benefit shall facilitate the presentation

and closure.

The lease will have a guaranteed minimum period of years of continuous operation. This will allow for constant exposure within the same Co. for future leases and possible demonstrations to other potential interested prospects.

With a guaranteed lease contract, CELLINI will approach the existing investors and/or bank institutions for the loans to build such Systems, eventually with on-going sales and cash flow we may, if so decided, fund our own future Systems construction.

cellini CAST technology inc.

2024

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.